— Products —

Professional grinding and manufacturing of tungsten carbide steel, non-magnetic tungsten carbide steel, zirconia, titanium alloy, nitinol components

. Ultra-precision punch, gauge, hexagon punch, extraction molding punch. Ultra-precision jig, pin gauge, bush, probe, shear tools

. All kinds of precision cutters

. All kinds of precision mechanical components

.Non-magnetic tungsten carbide components

.Nitinol components

.titanium alloy (Ti-6AI-4V ELI)

.Micro-hole processing and manufacturing (the smallest micro-hole diameter can reach Ø0.03mm)

※ Welcome to order all kinds of special specifications component

Revolutionary Precision in Micro-Groove Machining

We are proud to introduce our latest innovation: the 0.06mm micro-kerf tungsten carbide circular saw blade, designed for the highest precision machining needs. This micro-groove circular saw blade features an ultra-thin design, offering exceptional wear resistance and cutting accuracy, perfectly suited for machining high-hardness materials.

Product Features:

Ultimate Precision: With an ultra-thin thickness of 0.06mm, it delivers unparalleled fine cutting, meeting the highest precision machining requirements.

High Efficiency and Durability: Made from premium tungsten carbide, it boasts outstanding wear resistance and longevity, significantly enhancing production efficiency.

Specialized Application: Especially suitable for machining titanium alloy (Ti-6AI-4V ELI), ensuring each cut is stable, precise, and efficient.

Applications:

Our micro-groove circular saw blade is widely used in aerospace, medical devices, high-end manufacturing, and other fields that require ultra-high precision, providing exceptional cutting solutions for your products.

Choose our 0.06mm micro-kerf tungsten carbide circular saw blade to elevate your machining processes to new heights, precisely controlling every detail and achieving unparalleled product quality.

For more information, please contact us at info@tcpt.com.tw

Let's work together to create a miracle in future precision machining!

Process and manufacture tungsten carbide micro-mechanical parts, improved service life of parts, repeatability (positioning precision) is more stable.

Diameter of 0.21mm Micro-hole making on tungsten steel components with a surface width of 0.5mm.All industries are welcome to order products with special specifications。

Processing 0.05mm tungsten carbide steel micro-hole array

The tungsten carbide mold components are manufactured by precision machining, which are high hardness, high rigidity and wear resistance.

※ Welcome to order all kinds of special specifications components

Tungsten carbide mechanical components, nozzle, and micro-probe.

Precision tungsten carbide chamfering cutter, made of Japanese micro grain tungsten carbide, hardness with HRA 92.4, make the forming angle more stable, and the cutter of concentricity is making within 0.002mm. The precise front facet helps you to position the tool faster, more accurately and efficiently. The cutting edge is made with precision grinding and polishing technology, which makes your cutting surface smoothing and shinning. The cutting edge angle is finished under the microscope to ensure the cutting edge angle within ±0.5° (0°30'0").

[Welcome to order special

specifications cutting tools]

The tungsten carbide mold components are manufactured by precision machining, which are high hardness, high rigidity and wear resistance.

Ultra-precision

machining, the minimum outer diameter can be processed to Ø0.01mm (10μm)*0.5mm

height, welcome to order special specifications mold components.

Tungsten

carbide mechanical components are designed according to the needs of special

equipment, welcome to order special specifications mechanical components.

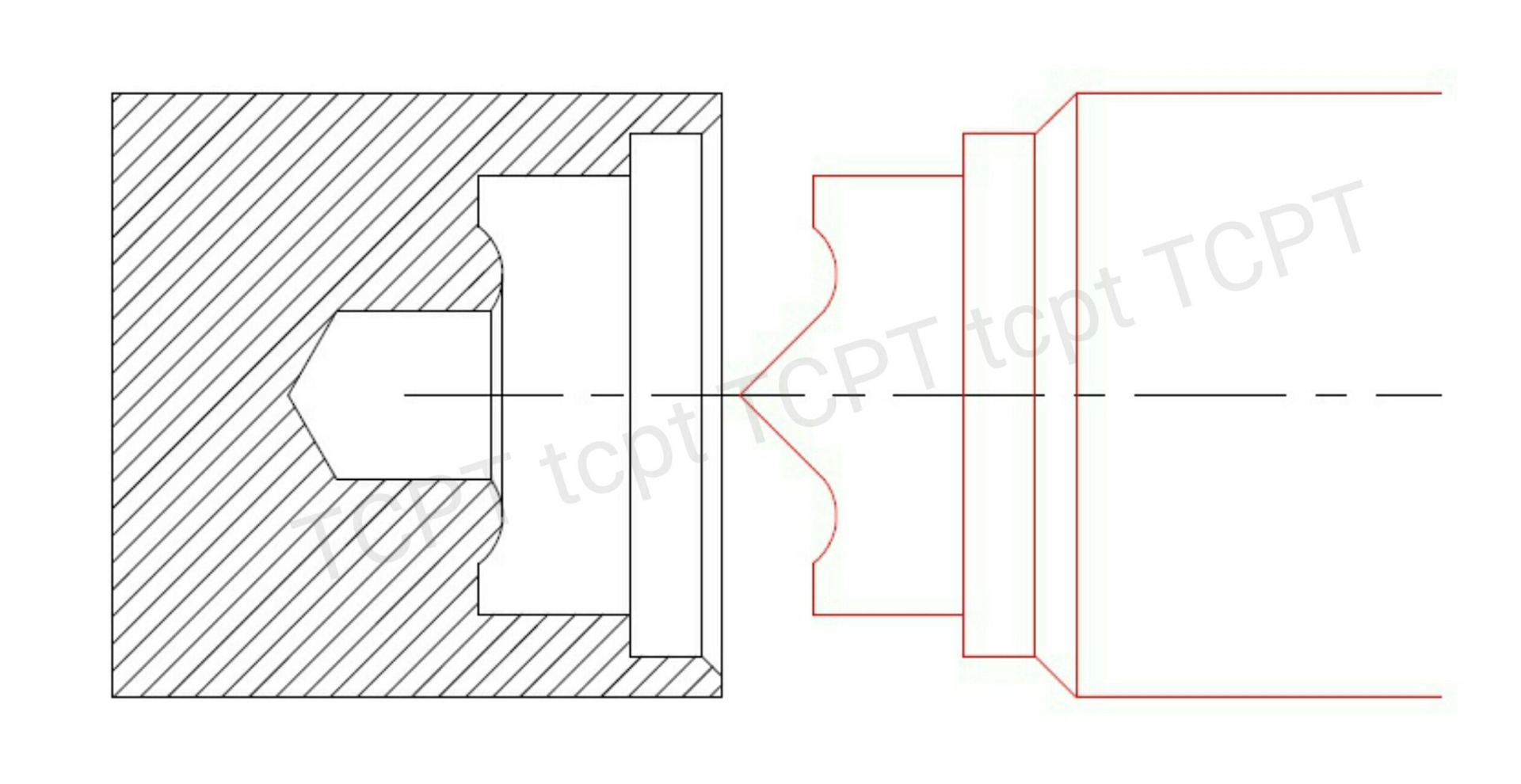

Ultra-precision

machining make the surface of extraction die more hardness and increasing the wear

resistance. We also design the most suitable R curvature to reduce the impact

resistance according to the customer's specifications.

Tungsten carbide base ball, measuring head, probe, one-piece molding processing, welcome to order special specifications.

Tungsten molding cutter, precision molding technology, help for shorten the process to improve efficiency and quality.

※ Welcome all sectors to order all kinds of special specifications